In the evolving realm of advanced manufacturing, materials like TPU Compound Film are increasingly being specified in custom thicknesses to suit highly specialized production demands. Shanghai MSD International Trade Co., Ltd. plays a key role in this sector, offering tailored TPU films that cater to industries ranging from aerospace to smart textiles.

The demand for custom thickness arises from the need for precise functional characteristics in critical applications. In aerospace interiors, for example, thin TPU films are used to laminate flexible panels that must be both flame-retardant and abrasion-resistant. In these settings, weight savings are essential, making custom-calibrated film thickness a performance and regulatory requirement. Shanghai MSD supplies TPU films with exacting tolerances, ensuring compliance with strict aviation standards.

For emerging sectors like wearable technology, the requirements are entirely different. Devices such as flexible sensors, fitness monitors, and soft robotics require TPU films that can stretch and recover without permanent deformation. These applications benefit from mid-range film thicknesses that offer durability without compromising comfort or movement. Shanghai MSD collaborates with R&D teams to fine-tune formulations that deliver optimal elasticity and breathability.

Another critical area is the protection of electronic devices, where TPU films are used in both protective casings and internal insulation layers. These layers demand different thicknesses depending on whether the goal is impact absorption or insulation from electrical interference. By offering a portfolio that includes antistatic, conductive, and thermally resistant versions, Shanghai MSD makes it possible to integrate TPU films at every stage of product development.

The manufacturing process of TPU Compound Film must meet rigorous standards to produce consistent results across a range of thicknesses. This includes control over extrusion speeds, cooling temperatures, and post-treatment techniques like corona or plasma surface activation. Shanghai MSD invests in advanced film extrusion lines and precision inspection systems that guarantee uniform gauge and excellent surface quality—key attributes for reliable downstream processing.

Sustainability is another key driver of interest in customized TPU films. By selecting only the thickness required for functionality, manufacturers reduce material waste and energy use during processing. Shanghai MSD further enhances its green credentials by offering recyclable and biodegradable TPU grades, helping clients meet evolving environmental targets without sacrificing product integrity.

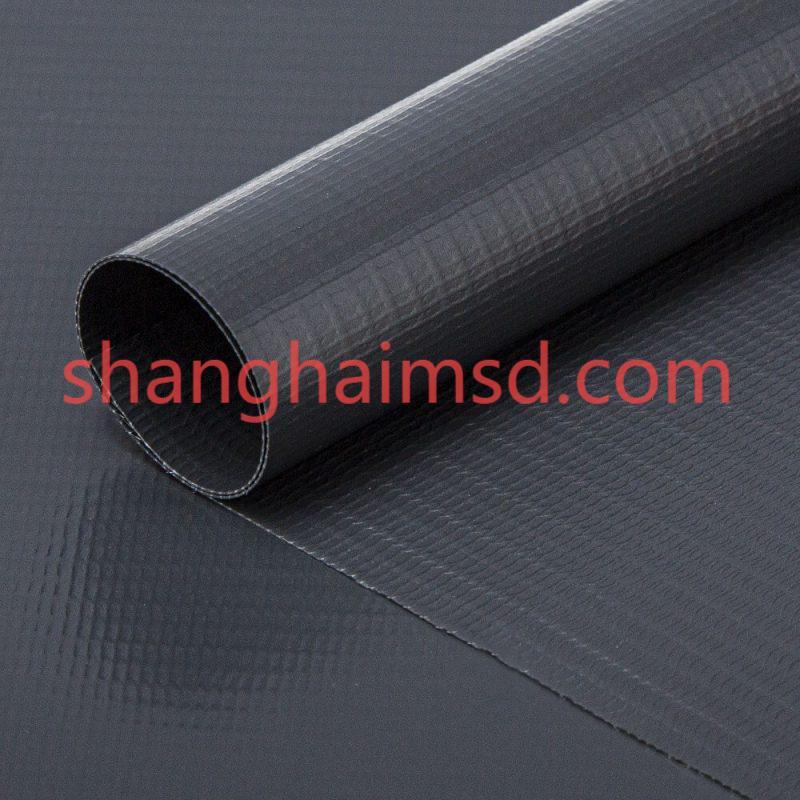

Shanghai MSD’s ability to deliver customized thicknesses across wide-width formats also supports large-scale production in construction, marine, and defense sectors. Whether for inflatable structures, chemical liners, or military equipment covers, the durability and adaptability of TPU compound films allow engineers to design with confidence, even in the most demanding conditions.Explore how customized TPU solutions from Shanghai MSD can enhance your next project at shanghaimsd.com .